Important Precursor Note:

This dowel pin modification is not strictly required for proper operation of the mechanical fuel pump or vacuum pump drive. To date, we have never had a drive back out in service.

However, we recognize that under certain conditions—

- Counter torque: As the engine drives the fuel pump or vacuum pump, a reactive force is created that tends to unscrew the drive bolt (which also retains the camshaft sprocket to the camshaft).

- High horsepower loads: Very large power levels amplify these forces.

- Vibration: High-RPM and high-power 2JZ engines naturally transmit vibration into the valvetrain and accessory drives.

These combined factors could, in theory, allow the drive bolt to loosen. The addition of a dowel pin provides an extra layer of mechanical security by positively locking the drive against rotation relative to the cam gear.

⚠️ Installer/Owner discretion:

If you are comfortable running the system without this modification, you may do so. This dowel procedure is offered only as an optional safeguard for extreme builds where the customer prefers maximum redundancy against drive bolt loosening.

Tools & Materials

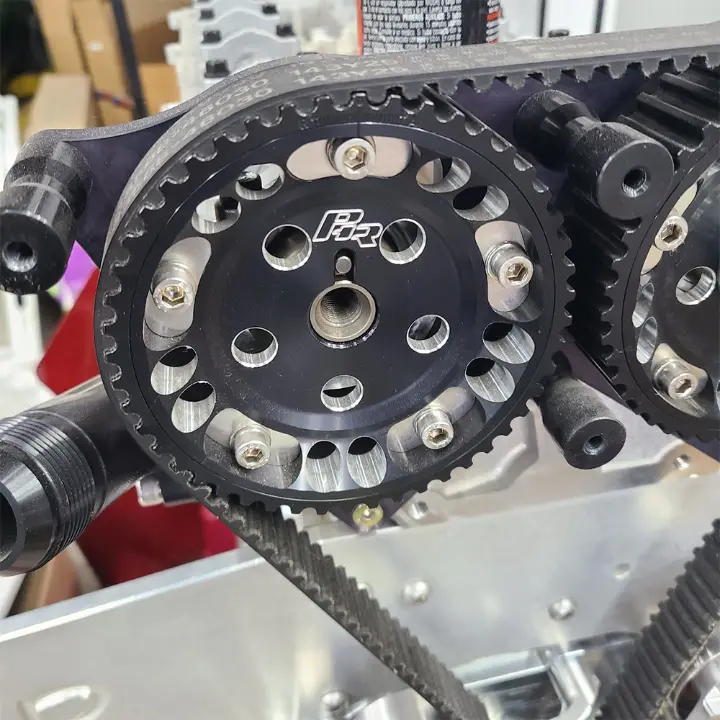

- PHR Drill Guide, drill bit and Drive Bolt (shown in Image 1)

- Hand drill (low RPM) and sharp drill bit

- Tape/paint pen to mark drilling depth

- Arbor press (or drill press used as a press) for installing the dowel

- Deburring tool or single-flute countersink

Identify the special tools

Lay out the Drill Guide and Drive Bolt. These locate and secure the guide concentric to the cam gear hub.

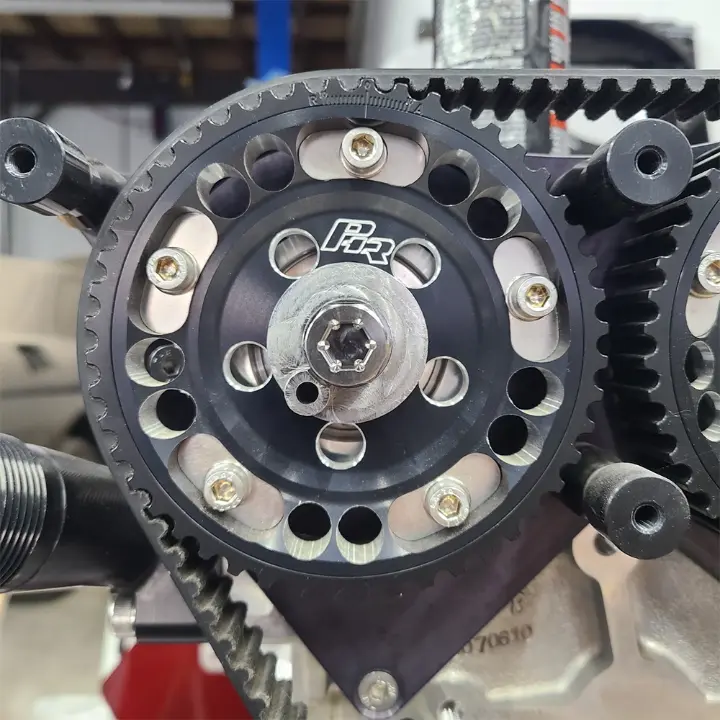

Prep the cam gear

Expose the cam gear hub/center bore. Blow off any debris.

Install the drill guide

Seat the drill guide against the cam gear face and secure it with the Drive Bolt. Snug the bolt so the guide can’t rock. The guide’s side boss is your drill bushing.

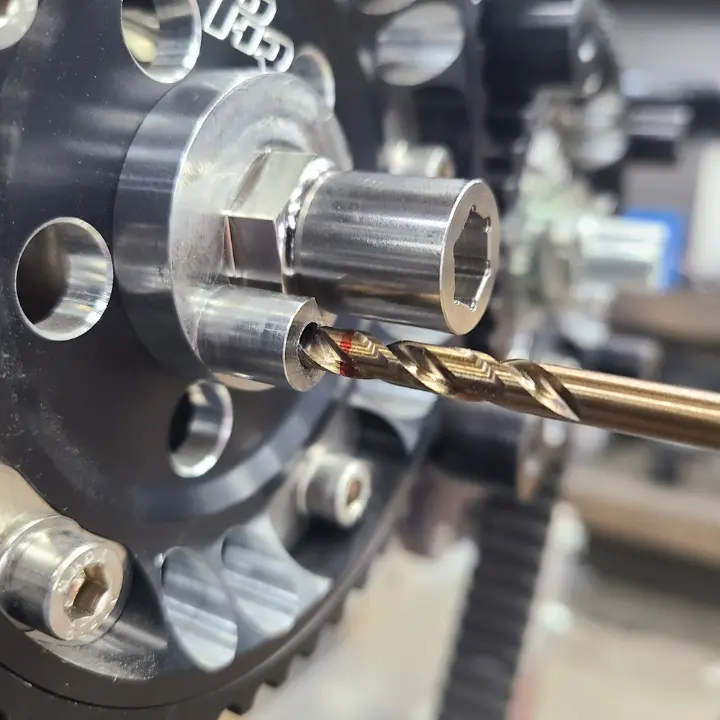

Mark your drill depth

Insert the bit through the guide to the target depth and mark the shank with paint/tape. Depth should be:

guide bushing length + desired dowel embed (do not break through into the threaded bore).

Drill the hole

With light oil and low RPM / steady feed, drill through the guide. Keep the drill straight and let the bushing do the locating.

Inspect the hole

Remove the guide and verify a clean, round hole. Deburr the entry lightly.

Press in the dowel

Support the gear flat and press the dowel straight in (arbor press). Drive it to the planned height (see Fit Notes).

Refit the gear

Reinstall the cam gear assembly with the new dowel visible and seated. Ensure no burrs interfere with mating parts.

Install the locking washer/retainer

Fit the drive’s locking washer over the hub. Confirm the washer clears the dowel and sits flat.

Install & seat the drive bolt

Install the drive’s center bolt through the washer and seat it. Torque to 58 ft-lbs.

Install the lock plate

Add the lock plate over the bolt head and secure its fasteners. Verify the plate fully engages the washer features and that the dowel aligns with the drive.

Note: If you are NOT going to install a dowel you do NOT need the lock plate. Just run it without it. Without the dowel, there is no reason to lock the bolt to the plate and therefore this just ads extra unneeded weight.

PHR Mechanical Fuel Pump Bracket Kit for 2JZ Non-VVT-i

PHR Mechanical Fuel Pump Bracket Kit for 2JZ VVT-i