PHR/Dailey Air Con Dry Sump System Builder for 2JZ

Converting to Dry Sump Oiling System

What are the benefits?

A dry sump system is an oiling system used in high-performance or racing vehicles. Unlike a wet sump system found in many production cars, such as the 2JZ, where the oil is stored in a pan underneath the engine, a dry sump system stores oil in a separate reservoir or tank, mounted externally.

Here's how it works and why it's beneficial:

- Increased Horsepower: The combination of reduced windage losses, improved oil control, better ring seal enhanced cooling, reduced crankcase pressures and better oil quality provided by a dry sump oil system all contribute to increased engine power. Follow as we delve into these benefits a little deeper.

- Reduced Windage: A dry sump system reduces windage by continuously scavenging oil from the engine's crankcase, maintaining a lower pressure environment. This decreases resistance to piston movement, allowing the engine to operate more efficiently and produce more power, especially crucial in boosted applications where every bit of power counts.

- Enhanced Oil Control and Quality: With a separate oil

reservoir,

adjustable oil volume and continuous scavenging, a dry sump system

promotes better oil control throughout the engine. This helps

prevent oil

starvation during high-G driving maneuvers and launches, ensuring

consistent lubrication to critical engine components. Also reducing

heat,

windage effects, better filtration and defoaming all lead to a

system that

will keep oil film quality up on your bearing and journal surfaces,

meaning increased health and longevity of your internals. The dry

sump pump will operate efficiently well beyond the normal rpm

limitations of typical sump setups.

- Improved Turbocharger Performance: In boosted applications, a dry sump system can also benefit turbocharger performance and health. By reducing the risk of oil contamination and leaks, it helps preserve the integrity of turbocharger seals and extends their lifespan, ensuring consistent boost delivery and overall engine performance.

- Reduced or Negative Crankcase Pressure: Creating a vacuum in the crankcase further enhances engine performance by offsetting positive crankcase created by combustion process. This minimizes resistance to piston movement, decreases blow-by, improves piston ring seal, and prevents oil seal failures, contributing to improved efficiency and reliability in boosted setups.

- Piston Oil Ring Seal: The effectiveness of piston ring seals is closely intertwined with the operation and performance of a dry sump oil system. By maintaining a tight seal, managing blow-by gases, reducing windage losses, and regulating oil control, piston rings contribute to the overall efficiency, reliability, and performance of a dry sump-equipped engine. Leading to better compression and increased performance.

- Engine Program Longevity: The consistent oil supply,

improved lubrication, and reduced stress on engine components offered by a

dry sump system contribute to increased engine program longevity and

reliability. This is particularly important in high-performance or racing

applications where engine durability is paramount.

- Space Considerations: In some high-performance applications, especially in vehicles with low ground clearance or tight engine compartments, a dry sump system allows for a shallower oil pan design. This can help with packaging and overall vehicle design, providing more flexibility in optimizing weight distribution and aerodynamics.

In summary, a combination of a dry sump system and maintaining a vacuum in the crankcase offers a comprehensive solution for optimizing engine performance in boosted applications. These technologies work together to reduce windage, improve piston ring seal, enhance oil control, prevent oil leaks, and improve turbocharger performance, ultimately enhancing overall engine efficiency, reliability, and power output while also providing benefits in packaging and design flexibility.

Dry Sump System Builder Guide

There are lots of options when building a Dry Sump System, our goal is to make the process as easy as possible. Below we will go over the various selection items for our kit. Once you add to cart you will have a chance to add on other accessories that will be needed to successfully run your system.

Block

As most of you know there are various 2JZ blocks, OEM, Mazworx, Bullet, Dart, ect.. Please choose the appropriate block and depth to work with your setup.

OEM - If you are running standard steel rods you will choose Standard or Deep Pan, if you are running aluminum rods you will Choose Deep Pan. If you Choose Deep pan you may need to clearance for the steering rack.

Mazworx - If you are running the Pro Street Billet Block you will order the Deep Pan

Bullet - If you are running Bullet select Deep Pan

Dart - If you are running Dart select OEM and Deep Pan

Pan Depth

Standard - This options applies to a steel rod setup on OEM block or Mazworx Pro Street Block. Total Depth is from Block Flange to Bottom of Pan (Outside) is 2"

Deep - This option applies to an aluminum rod setup for additional clearance at bottom dead center. You would also pick this option if you are running a Bullet, Block or Mazworx Pro Street. Total height from block flange to bottom of pan (outside) is 2.25". This option may require minor rack modification/clearancing.

Number of Stages on Pump

The oil pressure section constitutes stage #1, the remaining sections are assigned to crankcase. As the section number increases, the crankcase pumping volume is increased. 3 of the vacuum stages are fully integrated into the oil pan, this is part of the revolutionary pan design by Dailey Engineering. 1 section is assigned to the turbo oil drain.

Our AC dry sump

pump consist 5 stages. Because of the packaging constraints fitting both AC compressor and oil pump is same area, we are utilizing a smaller high speed version of Dailey's dry sump pumps. We would recommend this system to Circuit, Drift or Street

Cars. You

want oil control, solid crankcase pressure, and all the benefits of dry sump

oiling and would also like to keep your air conditioning. If you are shooting for the moon at a drag strip, we typically would recommend one of our standard 7 stage kits to increase scavenging volume.

This pump will not include any rear drive due to the space constraints

Parts Included

Our kit includes the following items;

- Proprietary Dailey Engineering Billet T6 6061 Oil Pan

- Dailey Engineering Dry Sump Pump

- HTD Taper grip pump pulley

- Belt Tensioner Arm and Pulley

- Belts

- Drive Set for the Dampner you are using

- HTD Crank Pulley

- Oil Filter Block-Off w/ Union adapter

- Installation hardware kit

- Sway Bar Spacer Set

Additional Recommended Items;

- Oil Tank

- Modified OEM Oil Pump or Billet Front Cover

- Remote Oil Filter Mount

- Pop-Off Valve(s)

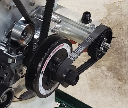

Pump Layout

Here is a pump diagram detailing hose routing, the -10AN scavenge is for you turbo oil drain.

Balancer Drive (Mandrel)

OUR KIT DOES NOT INCLUDE A CRANK BALANCER

However, we need to know which crank damper you are using so we can determine what drive mandrel parts we need to provide you with for your pulley and belt spacing.

Current options include Innovators West, ATI V1 and V2, and Fluidampr

Modifications to Fit

Due to the tight fitting nature of this kit, especially underneath the intake manifold, and dependent on the chassis it's going into, you may have to make some adjustments or modifications to your AC lines or other components in this area.

Deep Pan may require slight modification or clearancing of steering rack.

We will include spacers for your front sway bar.

Specifications

| Fitment | |

|---|---|

| Engine | 2JZ-GTE, Non VVT-i, 2JZ-GTE, VVT-i, 2JZ-GE, Non VVT-i, 2JZ-GE, VVT-i |

| Dry Sump Selections | |

|---|---|

| Block | OEM or Mazworx Pro Street or Bullet |

| Pan Depth | Standard or Deep |

| Balancer Drive (Mandrel) | Titan/ATI V1 or Titan/ATI V2 or Fluidampr or Innovators West |

| Pan Style | For Air Conditioning |

| Number Of Stages On Pump | 5 |

| Pump Return (Scavenge to Tank) | -16AN Return Fitting |

| Pumping Section Width | 1.2" (preferred) |

| Air Oil Separator | No |