Converting to Dry Sump Oiling System: What are the Benefits?

A dry sump system is an oiling system used in high-performance or racing vehicles. Unlike a wet sump system found in many production cars, such as the 2JZ, where the oil is stored in a pan underneath the engine, a dry sump system stores oil in a separate reservoir or tank, mounted externally. Here's how it works and why it's beneficial:

Increased Horsepower

The combination of reduced windage losses, improved oil control, better ring seal, enhanced cooling, reduced crankcase pressures, and better oil quality provided by a dry sump oil system all contribute to increased engine power. Let’s delve into these benefits a little deeper.

Reduced Windage

A dry sump system reduces windage by continuously scavenging oil from the engine's crankcase, maintaining a lower pressure environment. This decreases resistance to piston movement, allowing the engine to operate more efficiently and produce more power, especially crucial in racing applications where every bit of power counts.

Enhanced Oil Control and Quality

With a separate oil reservoir, adjustable oil volume, and continuous scavenging, a dry sump system promotes better oil control throughout the engine. This helps prevent oil starvation during high-G driving maneuvers and launches, ensuring consistent lubrication to critical engine components. Reduced heat, windage effects, better filtration, and defoaming all lead to a system that maintains high oil film quality on your bearing and journal surfaces, meaning increased health and longevity of your internals. The dry sump pump operates efficiently well beyond the normal rpm limitations of typical sump setups.

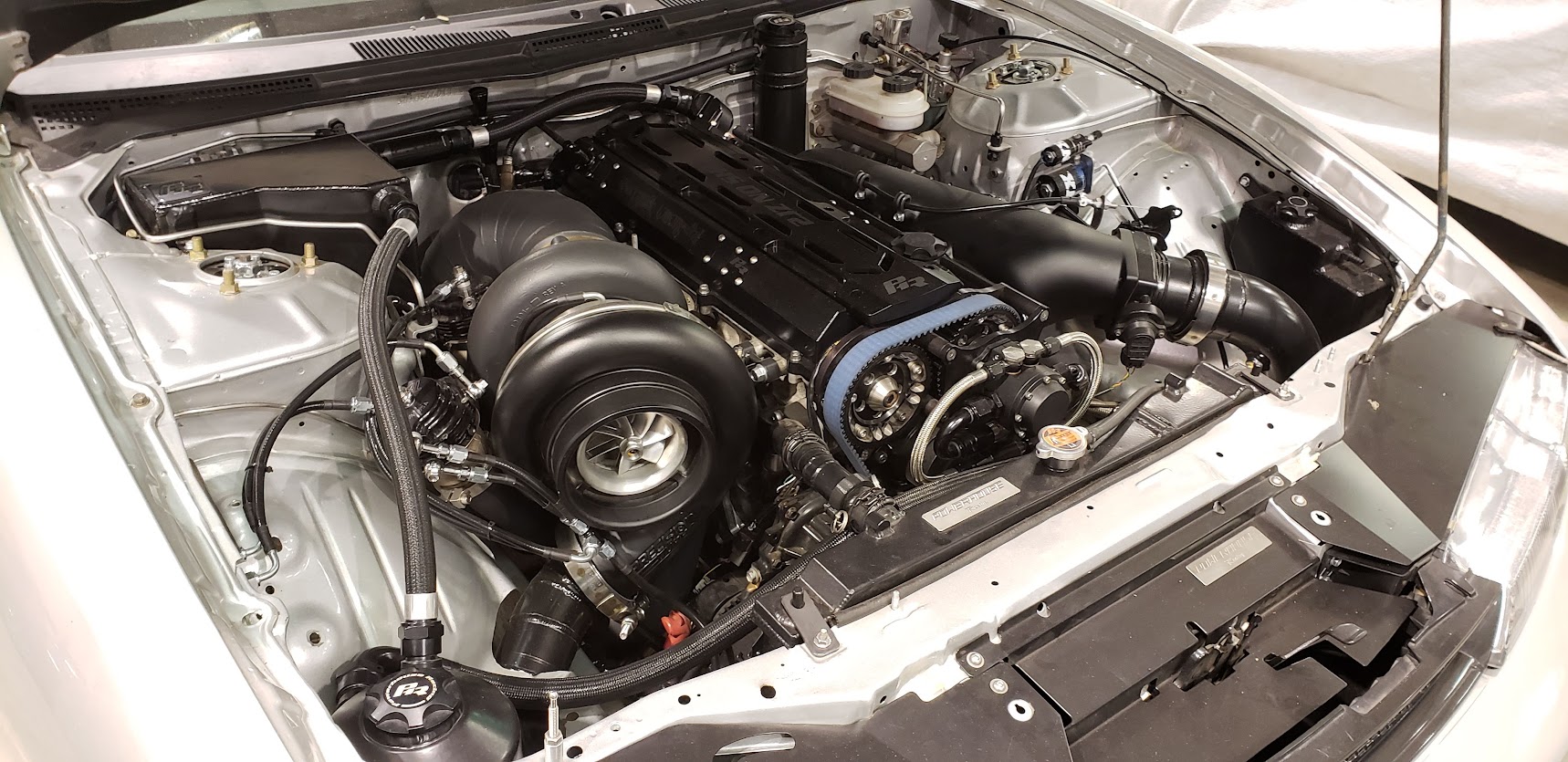

Improved Turbocharger Performance

In boosted applications, a dry sump system can also benefit turbocharger performance and health. It helps preserve the integrity of turbocharger seals as well the same consistent oil quality, ensuring reliable boost delivery, overall performance, and turbo longevity. In a PHR system we have dedicated a vaccum section solely to turbo drain which helps oil flow.

Reduced or Negative Crankcase Pressure

Creating a vacuum in the crankcase further enhances engine performance by offsetting positive crankcase pressures created by the combustion process. This minimizes resistance to piston movement, decreases blow-by, improves piston ring seal, and prevents oil seal failures, contributing to improved efficiency and reliability in boosted setups.

Piston Oil Ring Seal

The effectiveness of piston ring seals is closely intertwined with the operation and performance of a dry sump oil system. By maintaining a tight seal, managing blow-by gases, reducing windage losses, and regulating oil control, piston rings contribute to the overall efficiency, reliability, and performance of a dry sump-equipped engine. This leads to better compression and increased performance.

Engine Program Longevity

The consistent oil supply, improved lubrication, and reduced stress on engine components offered by a dry sump system contribute to increased engine program longevity and reliability. This is particularly important in high-performance or racing applications where engine durability is paramount.

Space Considerations

In some high-performance applications, especially in vehicles with low ground clearance or tight engine compartments, a dry sump system allows for a shallower oil pan design. This can help with packaging and overall vehicle design, providing more flexibility in optimizing weight distribution and aerodynamics.

Dry Sump System Setup Options

Building a dry sump system involves several options. Below, we outline the options and get into how and why you make the choices you do when picking out a dry sump to suit your needs.

Aftermarket Blocks and Pan Depth

Because a dry sump pan does not hold the full oil capacity or have a sump it can be extremely compact. However, stroking a motor can create a lower Bottom Dead Center, meaning you may need additional clearance. This is usually only a concern with aluminum rods which have additional material around the journal to retain strength on the lighter material.

This can also be a selection consideration with aftermarket blocks with taller main caps or new main cap designs as well mating surface and sealing changes. We have even designed a system to be compatible with AC compressor which normally is directly interfering with dry sump pump placement.

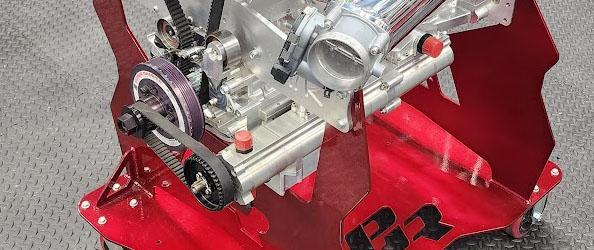

Dry Sump Pump Versatility

One of the more unique parts of dry sump oiling is an external pump does not suffer the same space constraints as an internal system. We are able to take our pumps and stack vacuum sections or increase gear sizes, pump speeds, change manifolds and inlets/outlets, add air oil separators, drive fuel pumps or cables, and much more.

The dry sump pump can be more than an oil management system and be fine tuned to your application. Powerhouse Racing offers pumps from 5 stages all the way to 10 stages. With a PHR kit you'll have options to fine tune your line routing which can be critical to chassis setup, installation, and compatibility.

Pump Options Can Be Found Here

Oil De-foaming

We touched on this above, the dry sumps ability to take air out of the oil. In standard format the screens found in our dry sump pans and external oil tank's baffling system does an excellent job or keeping up your oil film quality. If you are an endurance racer, that spends long duration under load you can add a driven air oil separator to the back of our oil pumps. This adds additional capacity to an already capable system. It will require a dry sump tank with dual inlets.

Balancer Drive

A dry sump pump is belt driven off the crankshaft. Kits include a drive mandrel off your crankshaft. Because there are multiple crank damper systems that effect spacing, bolt pattern and size. It's important to have the correct mandrel for your application.

What all is needed to complete my system?

Your kit will include an oil pan, oil pump, mandrel drive, and hardware and belts to complete all the items that are directly attached to your engine.

You have quite a few items that will need to be fit to your chassis.

Oil Tank

It's important to consider the oil volume that you will need. For 2JZ we normally recommend a 2 gallon tank. The shape and size of your tank, the mounting style, port location and size on your tank. Some tanks even accommodate oil warmers which you may like depending your climate, application, and engine clearances.

Remote Oil Filter Mount

Because the oil line routing is done externally, you will also have to mount your filtering system externally. This gives you some flexibility to use a larger race style oil filter, add priming drives, or additional oil monitoring sensors.

PHR Billet Remote Oil Filter Mount Found Here

Modified OEM Oil Pump or Billet Front Cover

Your OEM oil pump housing is no longer pumping any oil, but in a 2JZ, it is still necessary to seal your engine. You can modify your oem housing by removing the gear rotor set or look at aftermarket billet options which add some rigidity to your engine block. PHR's billet front cover also comes with the timing upgrades to help compliment your race program reliability.

PHR Billet 2JZ Front Cover Found Here

Crankcase and Oil Tank Ventilation Tank

Ideally, a dry sump crankcase, will exist in vacuum. However under certain unlikely conditions you still need the ability to vent your crankcase for safety concerns. Utilizing one way check valves on the breather lines from your engine, this will retain a sealed system under normal conditions. If your crankcase pressure goes positive, due to engine failure or due to boost levels exceeding your pumps suction ability, then the check valves can open to protect your engine seals.

In addition to venting the engine, you will also need to have a vent/overflow for you oil tank. This can be shared in the same system. A dry sump system will naturally balance it's oil level, so if you ever overfill your oil tank, it will also push to the catch can. Also often called a burn down tank or puke tank, it's important to size it large enough to contain your entire engines oil volume in cases of engine failures. This allows for safe containment on the race track. Engine Diapers are still recommended for more catastrophic events. Most burn down tanks are located in the trunk behind the rear tires for added safety.

Rear Mounted Breather Tank Found Here

Check Valves Found Here

Lines

One of the huge advantages to using a PHR and Dailey Dry Sump system is we have integrated the vacuum section directly into the pan flange thus reducing the lines you have to run in your entire system and potential failure points. Contrasted to many other options on the market which require lines to be run from pump to pan. We also have integrated turbo oil drain scavenge port. Additional vaccum section upgrades will require additional lines to crankcase. You will have to route all the connections between your oil pump, oil tank, oil filter, engine, crankcase and external vent tank.

Contact Us for Help with Custom Line Construction

Summary

In summary, a dry sump system combined with crankcase vacuum offers a comprehensive solution for optimizing engine performance in boosted applications. These technologies reduce windage, improve piston ring seal, enhance oil control, prevent oil leaks, and improve turbocharger performance. This results in enhanced overall engine efficiency, reliability, and power output, while also providing benefits in packaging and design flexibility.

Click Here to Option Out a 2JZ Dry Sump System