features these kit products:

- PTE Turbo

- PHR Street Torque Cast Manifold

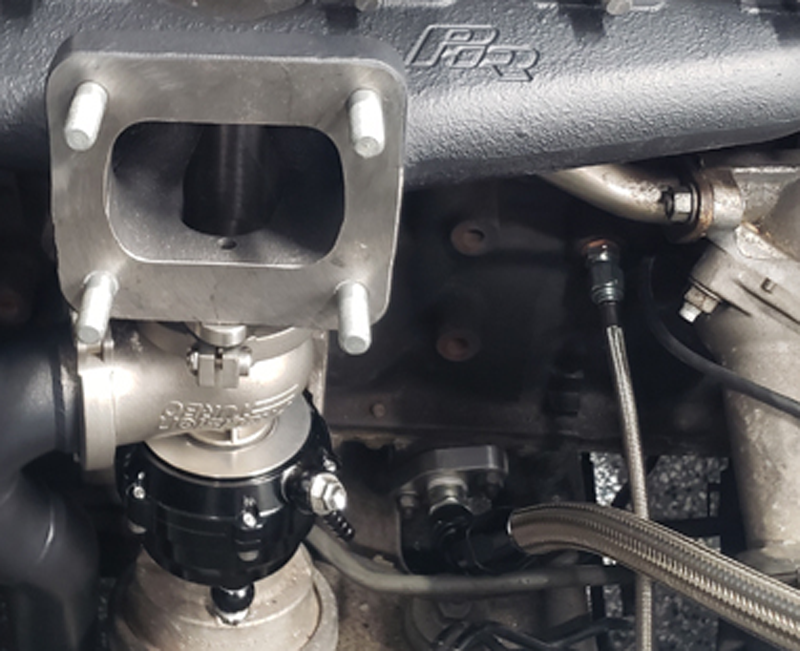

- PTE 46mm Wastegate and PHR WG Adapter

- PHR 3.0 Downpipe

- PHR Dumptube to Atmosphere

- PHR 4.5" Intercooler Kit

- PHR 4.0" Intake Kit

- PHR Oil Feed and Drain Lines

- PHR Lower Waterneck Rotator

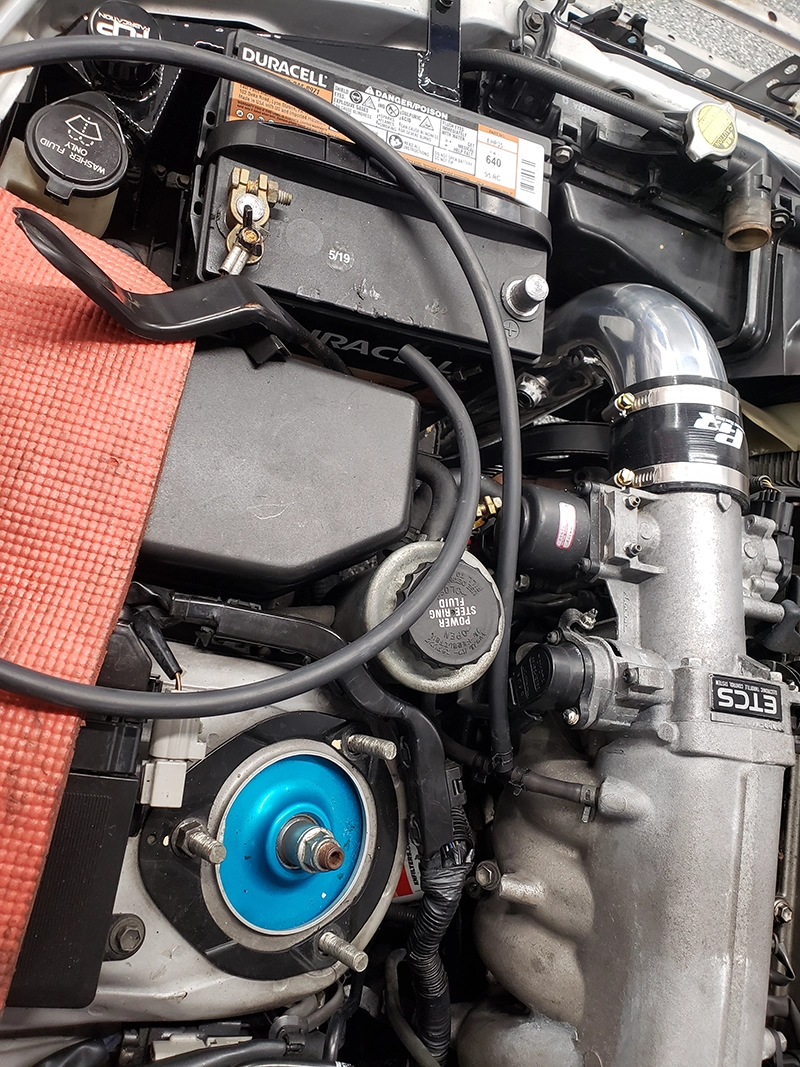

Step 1:

Start by removing all OE twin turbo components. Replace OE manifold studs if preferred but not required. If reusing OE studs, shortening of the third and fourth stud in from the left on bottom row are required for manifold to be installed properly. Replace turbo manifold gaskets. For ease of install, first install wastegate adapter then loosely install wastegate (make sure wastegate is properly assembled with correct/desired springs to set base system boost pressure) prior to installing the manifold. Install turbo mounting studs, turbo oil drain block fitting, turbo oil feed fitting and line, and drain line(leave loose for now). If your Supra has an automatic transmission slight bending of the trans cooler lines may be required to install turbo drain fitting and line. Finally install manifold and tighten mounting nuts.

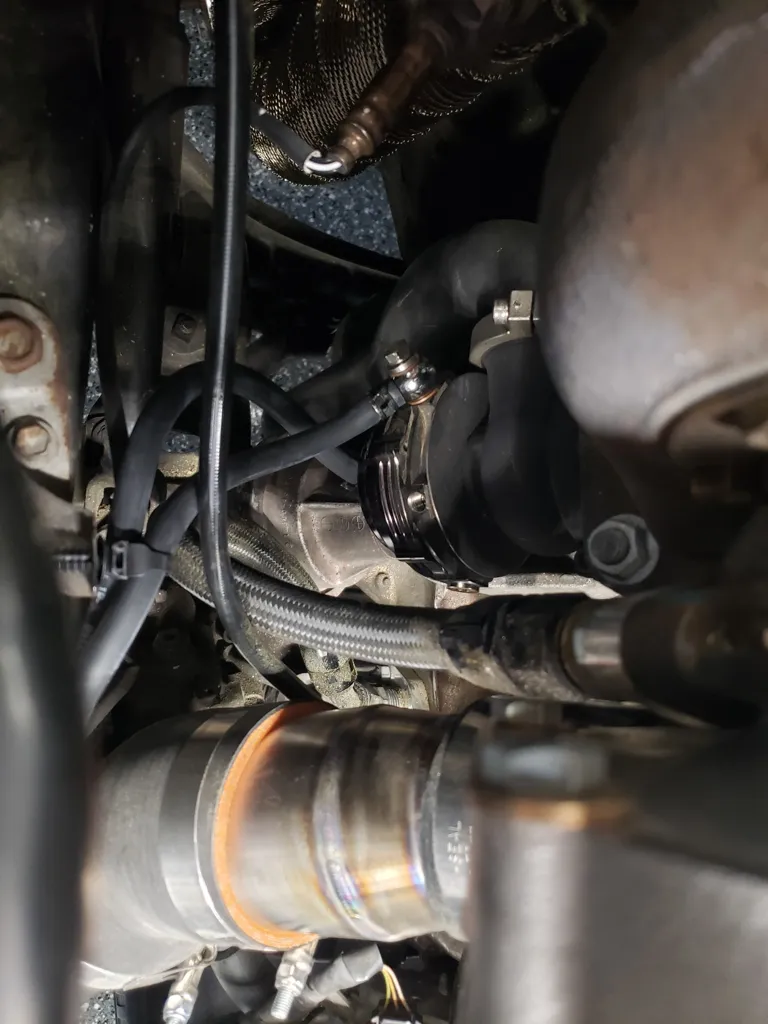

Step 2:

Loosely install wastegate dump tube. Then rotate wastegate and dump tube independently until dump tube is positioned correctly and point into opening by subframe. Do not point dump tube directly at subframe or any other components on vehicle. Tighten wastegate and dump tube clamps.

Step 3:

First remove turbo from box and remove the center housing mounting bolts and separate the turbine and compressor housings from turbo.

Install turbine housing gasket, then install turbine housing.

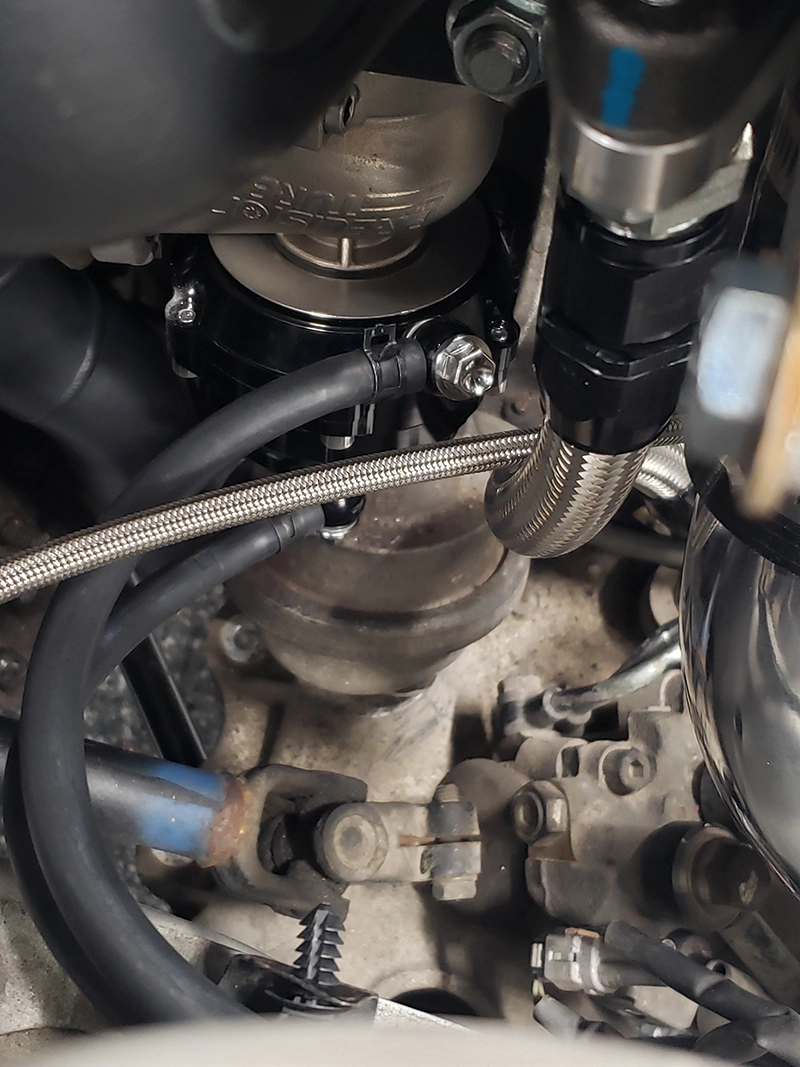

Step 4:

Loosely install turbo center housing and compressor housing. For ease, pre-install turbo drain fitting and gasket/O-ring onto center housing. Rotate center housing till the drain is pointing down in the 6 to 7 o'clock position, then tighten turbine to center housing mounting bolts. Make sure to leave compressor housing loose enough so it can still rotate. Install and tighten turbo oil feed and drain lines and orient them appropriately on the top and bottom of the center housing of the turbo.

Step 5:

Loosely install downpipe on the back end of the Turbo housing.

Step 6:

Make connection between downpipe and midpipe (if full length downpipe was ordered), or between Street Torque downpipe and OE twins style downpipe(if short downpipe was ordered). Install v-band clamp (shown) or mounting bolts and gasket (not shown). Make sure downpipe is positioned properly and not making contact with anything. Rotated down pipe and necessary if need to correct misalignment then tighten the v-band clamp connecting the downpipe to turbo.

Step 7:

refer to the Toyota workshop manual to remove the front bumper cover (not shown), front crash bar, plastic air diverter trim panel, and the OE Coolant overflow reservoir, power steering line mounting bolts, and OE condenser fan.

Step 8:

Reinstall power steering mounting bolts and gently bend power steering lines towards a/c condenser to make clearance for intercooler.

Step 9:

Find and position something suitable to support the new intercooler for install (detailing seat shown) and set the intercooler onto your support positioned in previous step.

Step 10:

Using a tie strap, temporarily move and strap the hood release cable up and away from intercooler so that it will not be in the way or become pinched by intercooler during install.

Step 11:

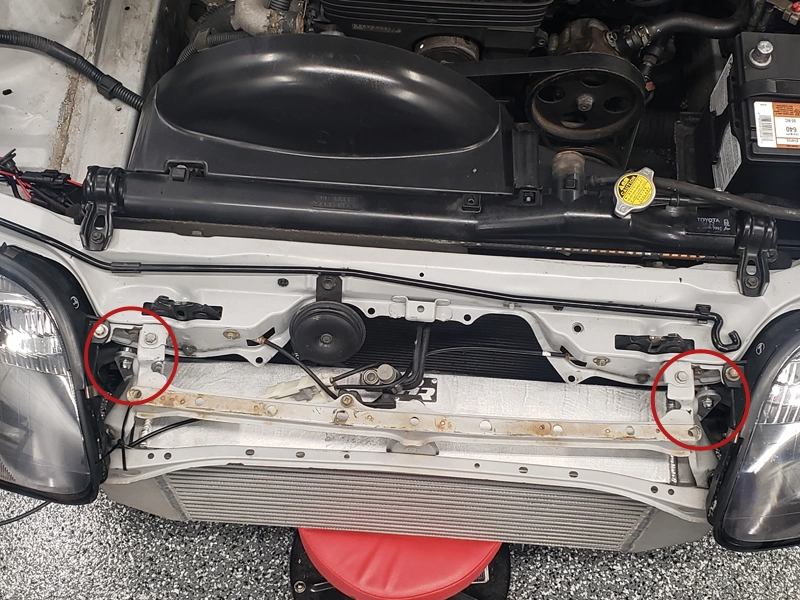

Move intercooler into position and align mounting tab holes with the existing holes in radiator support below hood latches.

Step 12:

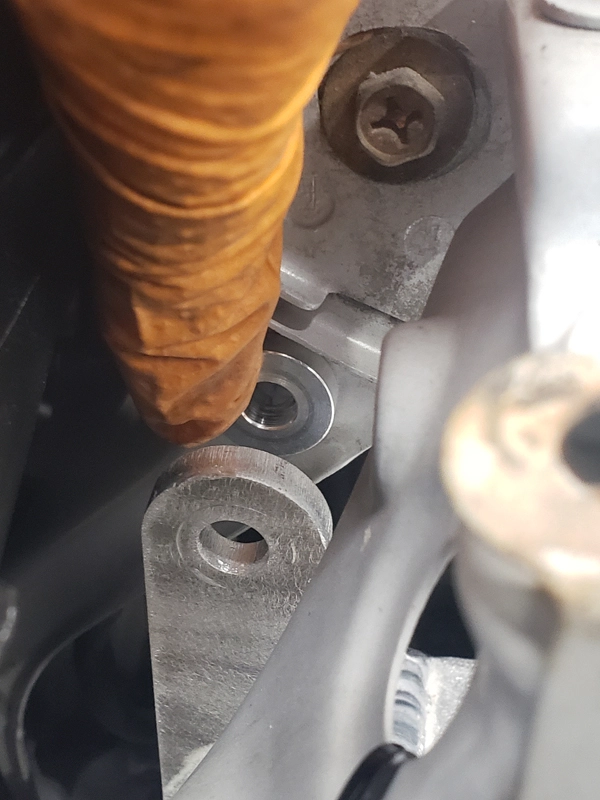

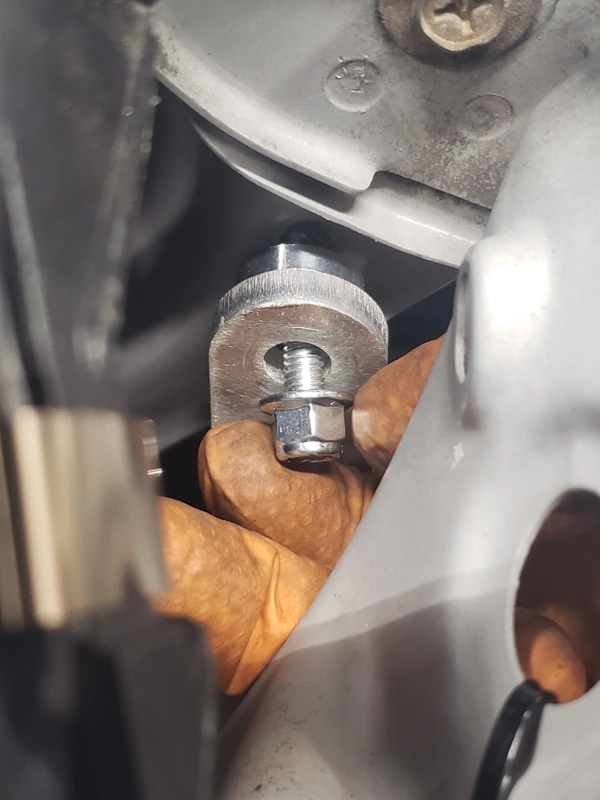

while holding supplied intercooler mount spacer in place, install the supplied M6 bolt of appropriate length. Then slide intercooler onto mounting bolt and loosely screw on the M6 locking nut. do for both sides.

(Upper mounting bolt size: M6 - 1.0 x 30 Cap Screw)

Step 13:

Remove whatever support you are using, and allow inter cooler to hang from M6 mounting bolts installed during previous step.

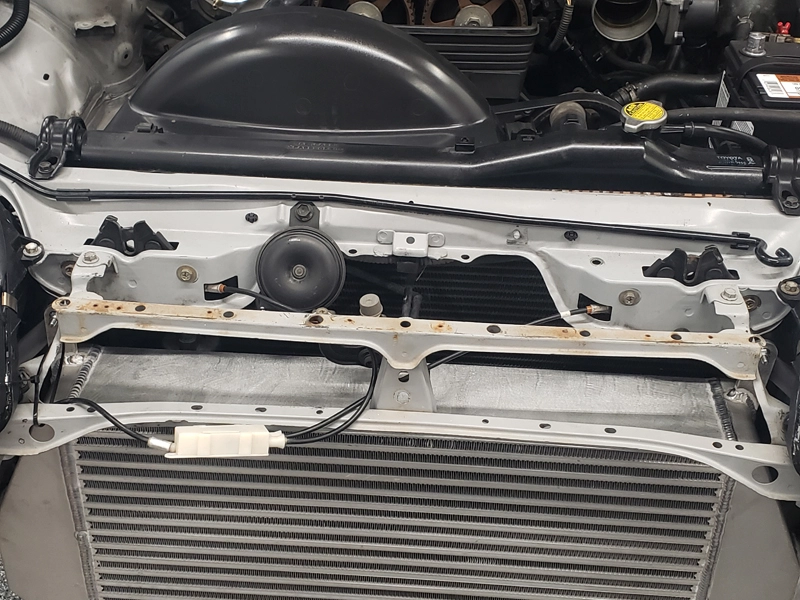

Step 14:

Loosely install lower intercooler support bracket using supplied bolts and push/pull intercooler into position so that it is not tilted inwards or outwards, but rather straight up and down. use a leveling device to make an more accurate position. once intercooler is in the desired position, tighten the lower support bolt, then the upper mounting bolts. check and correct position if needed.

Step 15:

Route hood latch cable and bracket and mount using tie straps and factory mounting nut and bolt in existing hole in radiator support.

Step 16:

Using an appropriate tool, bend the tabs on frame rail near the intercooler inlet and outlet to gain clearance for charge pipe coupler. repeat on both sides.

Step 17:

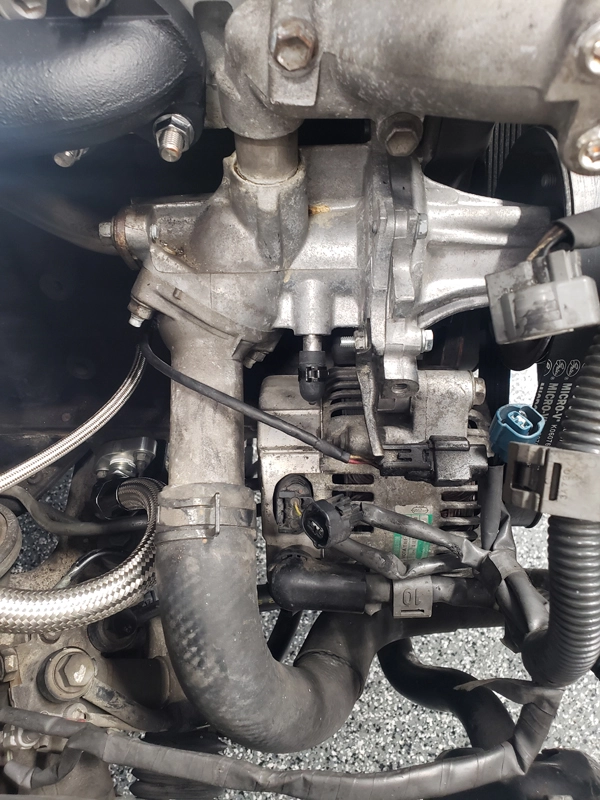

On RHD Supras a PHR lower water neck rotator is required for charge pipe clearance due to power steering rack and line positioning. On LHD Supras a PHR lower water neck rotator is not required but is recommended for optimum clearance.

Remove lower water neck and factory mounting studs. Clean/sandblast factory lower water neck for reinstallation.

Step 18:

Install thermostat with seal into PHR lower water neck rotator. Position thermostat vent hole facing upwards, and Install the rotator and thermostat using supplied hardware onto water pump outlet.

Step 19:

Install supplied water neck gasket and gasket support ring into factory lower water neck and Install lower water neck onto rotator with water neck facing straight down using supplied hardware.

Step 20:

Either cut/modify then install factory lower radiator hose or install a PHR rotated silicone lower radiator hose (recommended).

Step 21:

Loosely install couplers onto both inlet and outlet of intercooler. The 2.5in to 3in adapter coupler goes on the intercooler inlet (sometimes called hot side or turbo discharge side).

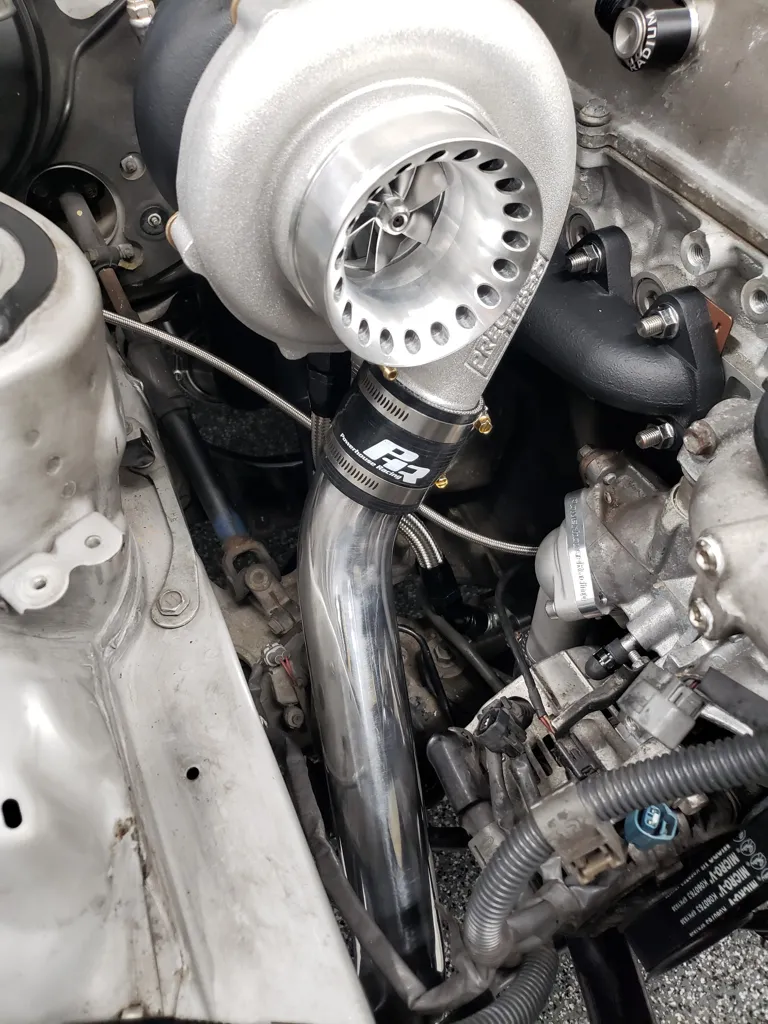

Step 21:

Loosely install turbo discharge pipe and route it under the sway bar. Make sure it is routed so that it will not come into contact with anything, such as: the alternator, power steering rack or lines, sway bar, or misc. wiring. Rotating the turbo compressor housing will most likely be required for proper charge pipe routing.

Step 22:

At first loosely install intercooler inlet charge pipe onto turbo discharge pipe and then into the intercooler inlet coupler. Once properly in position and with adequate clearance tighten all 6 supplied clamps as well as turbo compressor housing mounting bolts so it can no longer rotate.

Step 23:

On left side remove a/c line to frame rail mounting bolts and lower the line down for easier access.

Step 24:

Using a large pair of vice grip pliers clamp down on the a/c line fittings so that you may remove there mounting brackets without releasing/discharging the a/c system.

Step 25:

While clamped in the vice grips remove the factory m6 nut and mounting bracket. Then install the M6 bolt acquired in previous step along with factory M6 flange nut and tighten.

Step 26:

Remove vice grip pliers and repeat on the other a/c line. below is a view of M6 bolts installed and factory a/c line mounting brackets removed.

Step 27:

Gently bend a/c lines down to gain clearance for charge pipes.

Step 28:

Depending on your model year of Supra as well as whether its auto or manual transmission you may have a radiator fan connector that needs to be repositioned for clearance. Remove it with its mounting clip from the radiator fan bracket

Step 29:

Remove the top mounting bolt of the radiator fan bracket and move fan bracket slightly to slip fan electrical connector onto opposite side of fan bracket and re clip in place using same clip hole in bracket. Reinstall top mounting bolt of fan bracket. If additional clearance is required in the following steps some grinding/material removal of the factory radiator fan bracket my be required.

Step 30:

Gently route/bend the lower of the 2 power steering lines down for charge pipe clearance.

Step 31:

Loosely install throttle body inlet pipe and coupler onto throttle body. Check for clearance issues all around the pipe.

Step 32:

Install intercooler outlet pipe to throttle body inlet pipe then into coupler on intercooler outlet.

Step 33:

check and adjust for clearance between lines, charge pipes, and frame rail so that adequate clearance is had by all components and that no contact is made between any of them.

Step 34:

begin to tighten all 6 clamps starting at throttle body inlet coupler, while double checking for adequate clearance all around throttle body inly pipe. Adjust and recheck as necessary.

Step 35:

Preassemble BOV as needed per BOV manufacturer instructions based on engine idle vacuum. Some BOVs come with different springs while others have adjustment spring spacers. Most healthy 2JZGTE (non-vvti) engines produce about 20(+/-2) inches of vacuum at idle. Once properly assembled install BOV onto intercooler outlet pipe BOV flange. Make sure the O-ring seal is properly installed between the BOV and the flange.

Step 36:

Cut and install a 1/4in vacuum tee into factory power steering idle up switch vacuum line. If power steering idle up switch has been disabled skip this step. (Use 10 x 10mm hose clamps on all 1/4in vacuum connections to ensure no leaks with develop(especially at high boost)

Step 37:

Measure and cut a 36in section of 1/4in vacuum hose if not supplied in kit and install onto tee from previous step

Step 38:

Route vacuum line down frame rail and over sway bar,

Step 39:

then route vacuum line down under the windshield washer reservoir and up towards BOV

Step 40:

Install vacuum hose onto BOV vacuum port and rotate BOV vacuum port until adequate position is found, then tighten BOV vacuum port banjo fitting

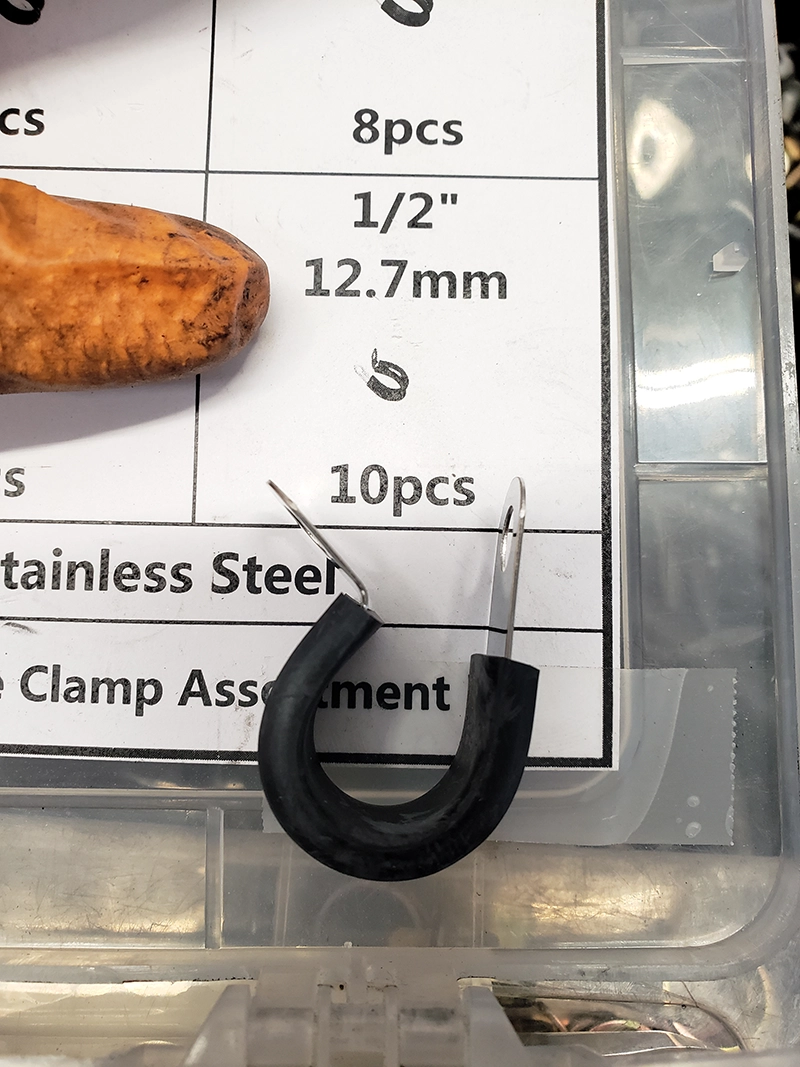

Step 41:

Install a 1/2in cushioned p-clamp (should be provided) around BOV vacuum hose and onto left side frame rail using an M6 bolt that was removed from the a/c line mounting brackets in previous step. An existing m6 threaded hole is used on left side frame rail.

Step 42:

Install turbo air intake coupler onto turbo, then the air intake pipe into coupler on turbo, then the air filter onto air intake pipe. Position filter, pipe, and clamps as necessary. Then tighten all clamps.

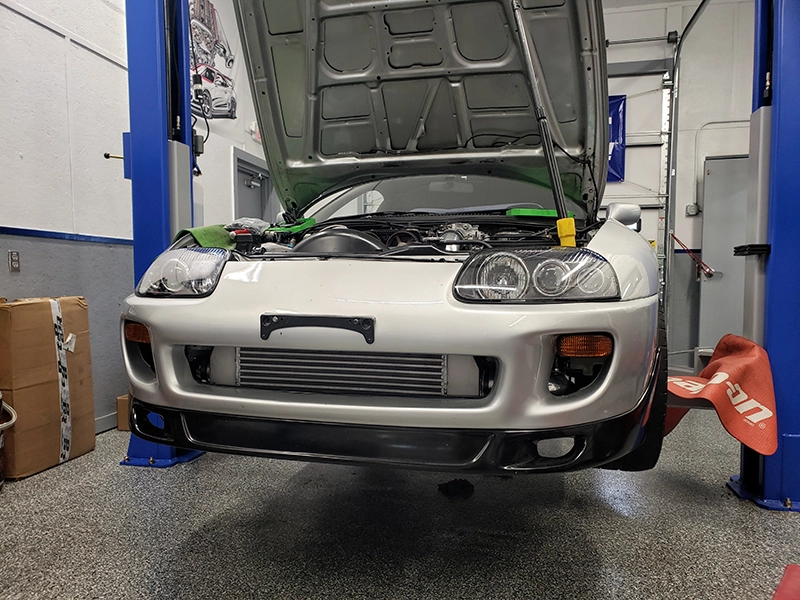

Step 43:

Depending on what front bumper cover your Supra has some modification may be required for it to fit/reinstall properly. The following steps outline how to modify the bumper cover

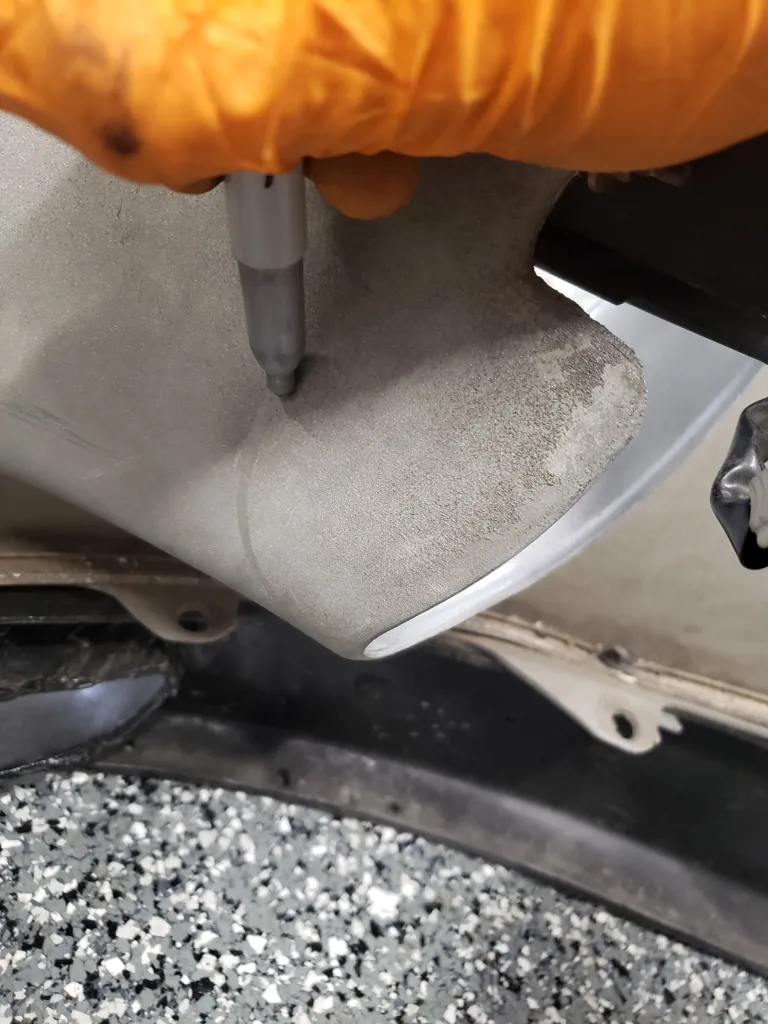

Step 44:

Test fit the bumper cover to see where the bumper cover contacts the intercooler pipes and needs to be modified. Then mark that area of the bumper cover.

(Tip: install painters tape on the painted side of bumper cover where ever modifications need to be made.)

Step 45:

Use a Dremel and a router bit to make rough cuts where you previously marked the bumper cover for modification.

Step 46:

Once rough cuts have been made, test fit bumper cover and repeat that process as required till bumper cover fits properly. Once no more rough cuts need to be made and bumper cover fits properly use a small orbital sander and a 1inch sanding disc(fine grit) to smooth out the rough cuts and provide a natural and smooth contoured look back to the bumper cover.

Step 47:

Remove the previously installed painters tape, and reinstall bumper cover for final time using all the factory mounting hardware and support brackets.

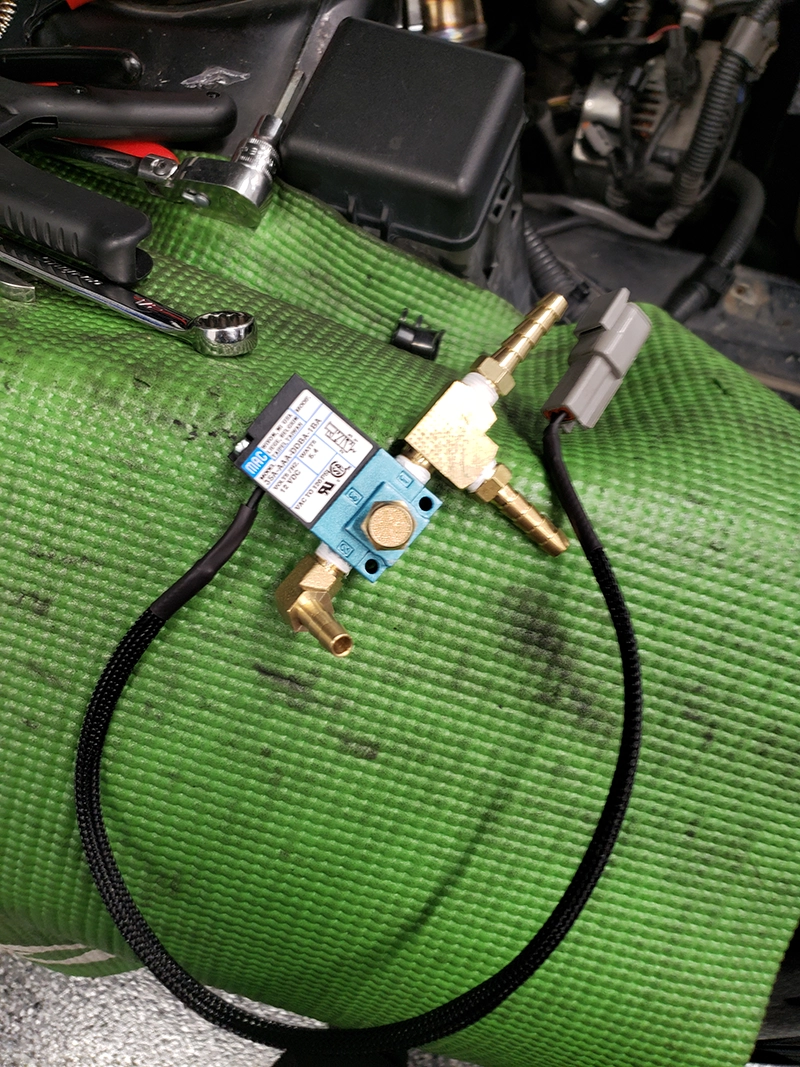

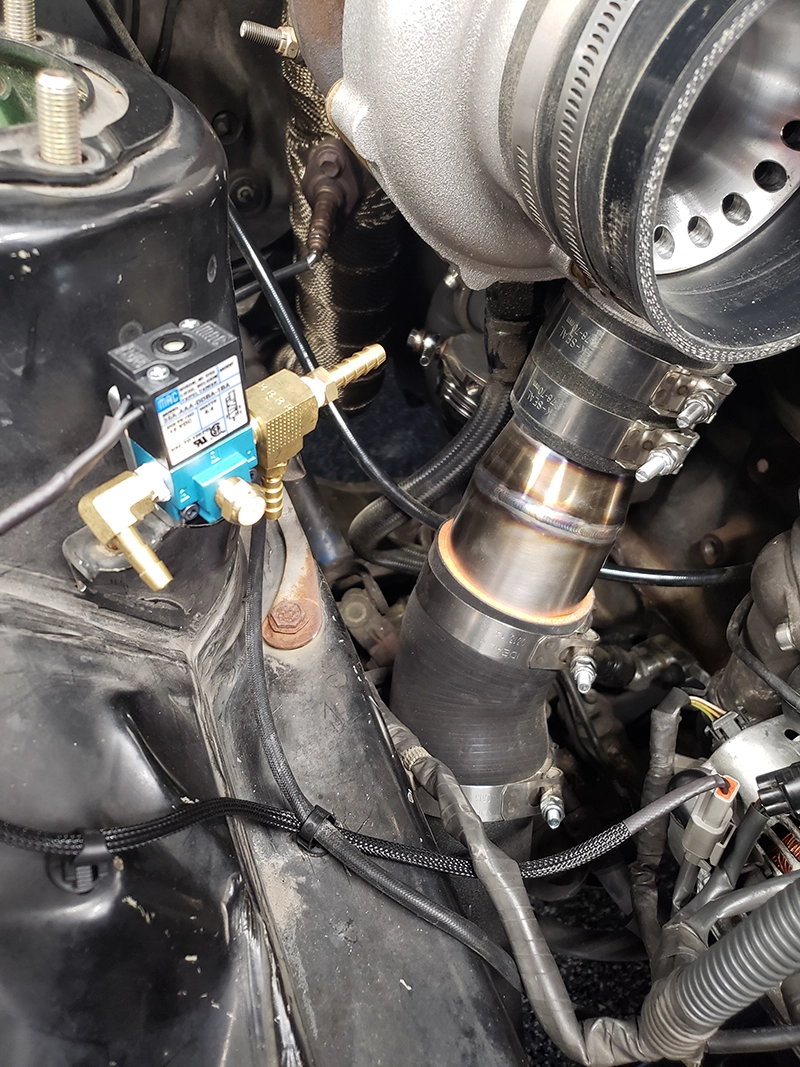

Step 48:

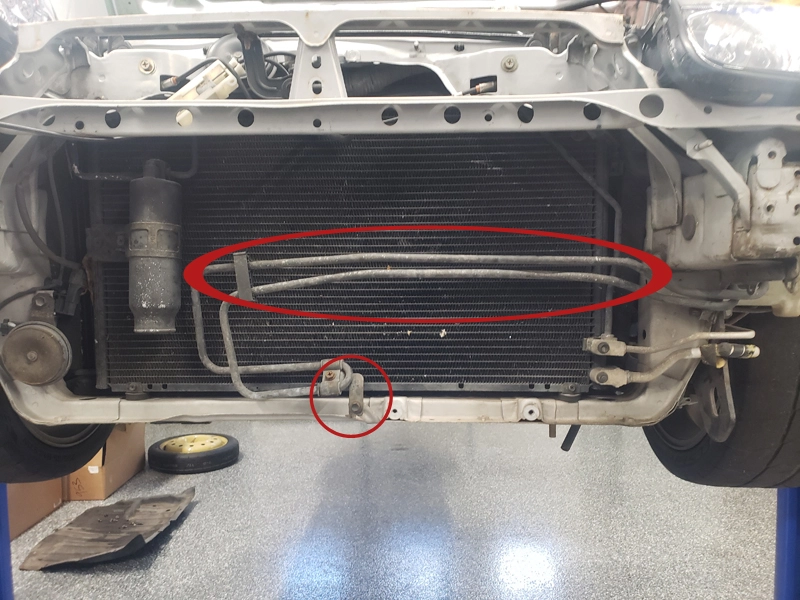

If you opted for electronic boost control with your kit then install solenoid and lines similar to this.

View of boost control lines installed on wastegate. Once lines installed, tighten boost control banjo fittings on wastegate.

Your Street Torque Turbo Kit is now installed and ready